The project was started in mid August 2014 by cutting the firetruck down. Some of the aluminum compartment doors were saved, but most of the body, the pump, and cab were scraped. Cab cut down short enough to fit into shop.

Click on the pictures below to enlarge.

The needed components such as the air tanks, steering box, and axles were removed and engine and transmission pulled.

After everything was removed from the frame, the engine was blocked up on the floor and frame was built around it. A short section of the C-channel frame was used because of it's nice bend seen in one of the pictures below.

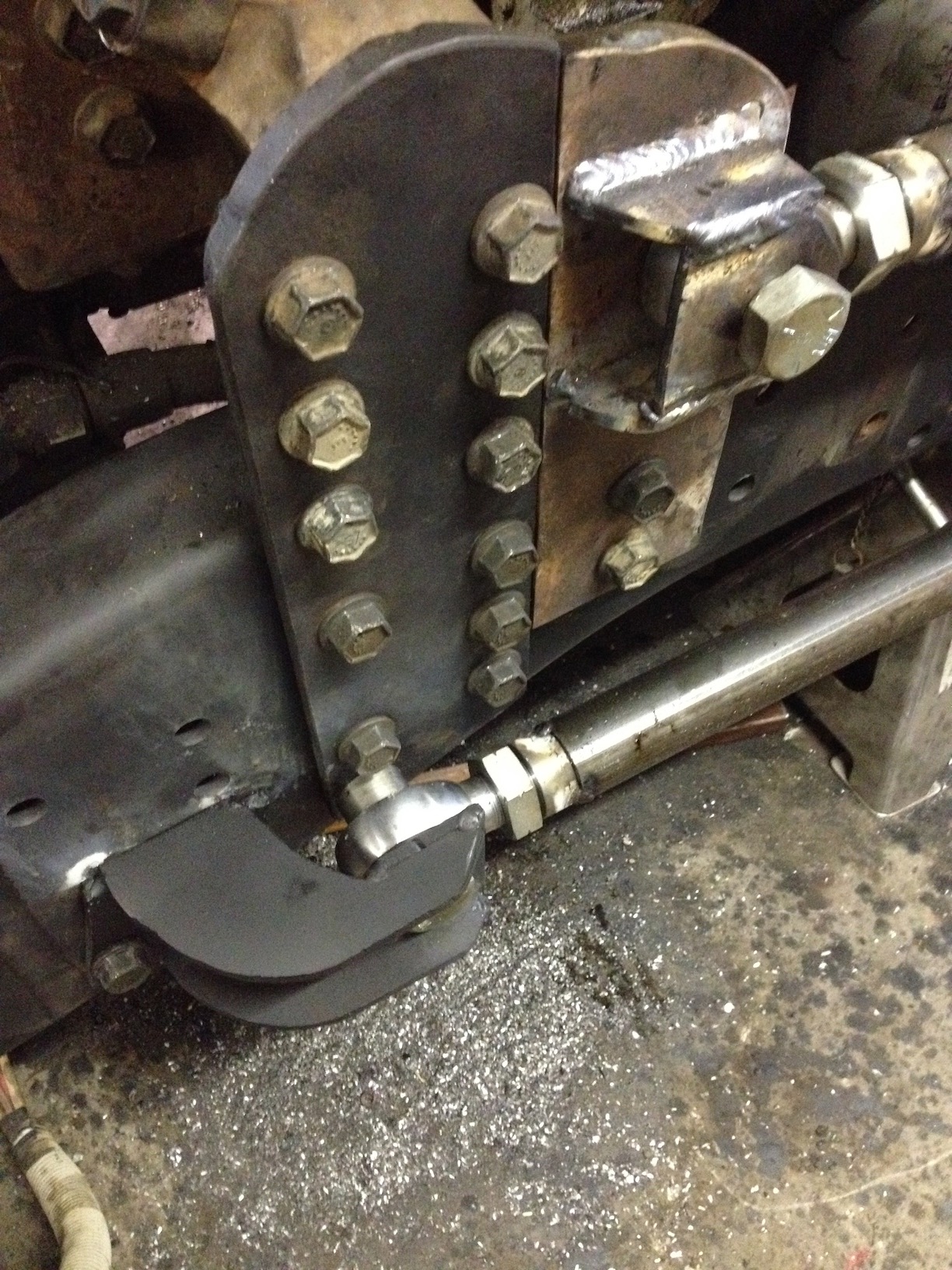

The remainder of the frame was built using rectangular and square steel tubing with approximately 45 pounds of welding rod. The air bags have a 21 inch travel, so Watts Links were built and used on both axles. Watts Links were used instead of panbars because they do not 'pull or push' the axle with height travel.

Click on the pictures to enlarge

The turbocharger was moved from the top of the blower to the front of the engine. The cab was fitted to the main frame. the truck bed was fabricated and sheet metal was bent and fabricated to look like a welder. The 'Welder' is just a cover for the radiator that was mounted behind the cab. The driver's door was 'suicided'. The cab interior is covered with decommissioned firefighter bunker coats. NOS was added 'just because'. (It will however, brake the tires loose for a burn-out and hit third gear before they stop spinning.)